Our Micro- and Ultra-Filtration System – Type MEMZEP 007

Background

In the processing and food industries, classical types of filtration, like precoat filtration, which are used to separate minor mass fractions from suspensions, are being replaced by membrane filtration concepts.

The use of filtration aids like infusorial earth or silica gel is no longer entirely uncontroversial in food engineering. Therefore, membrane filtration is becoming increasingly important to the process steps after fermentation responsible for separating biomass.

The targeted isolation of proteins and dyes also requires precise separation, which can now be achieved thanks to the wide range of available membrane materials and separation limits. Membrane processes such as micro-filtration and ultra-filtration are already very well established in fruit juice and beer production too. These processes have great potential for future applications with the multitude of new product combinations.

General Technical Description

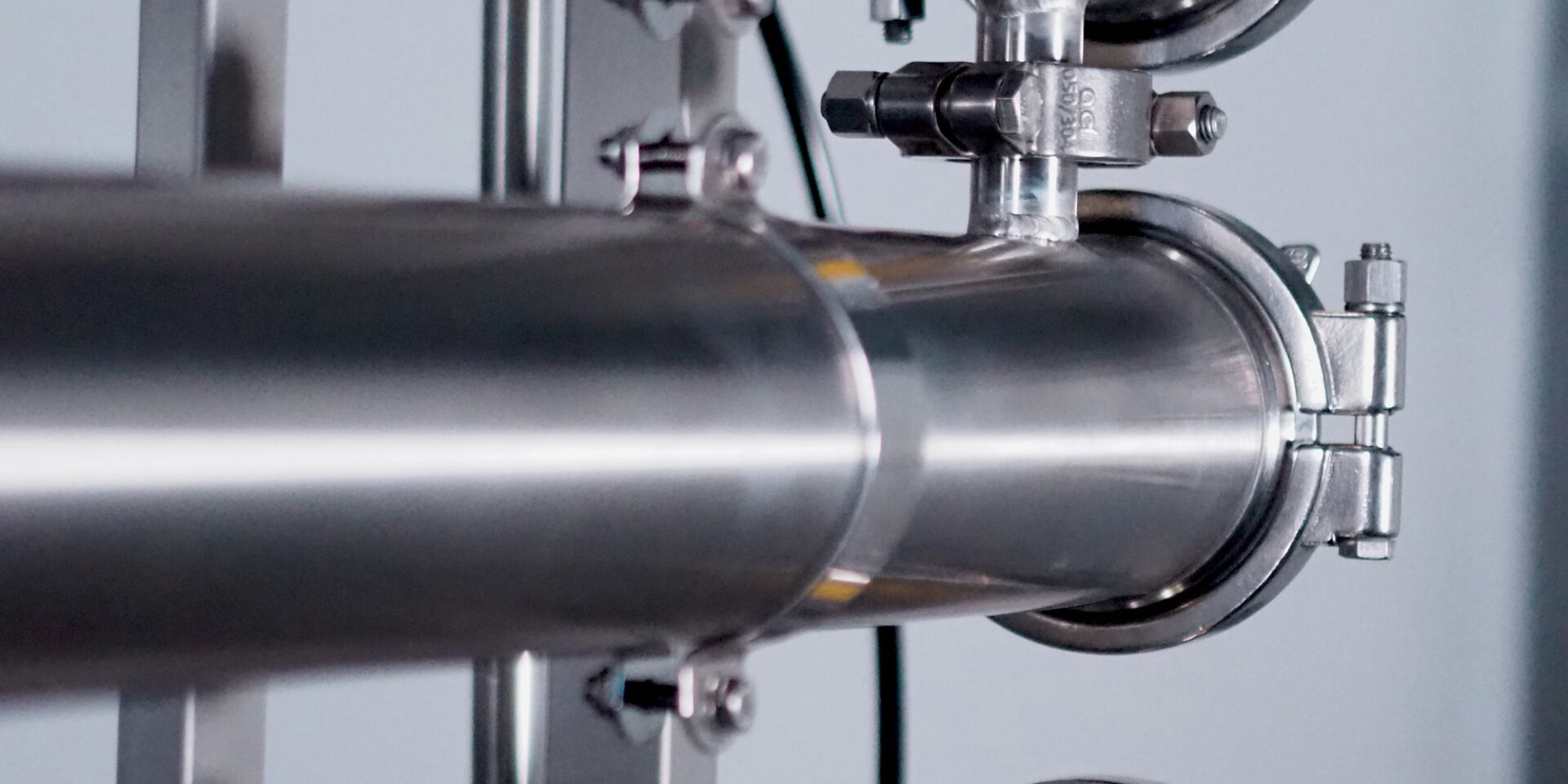

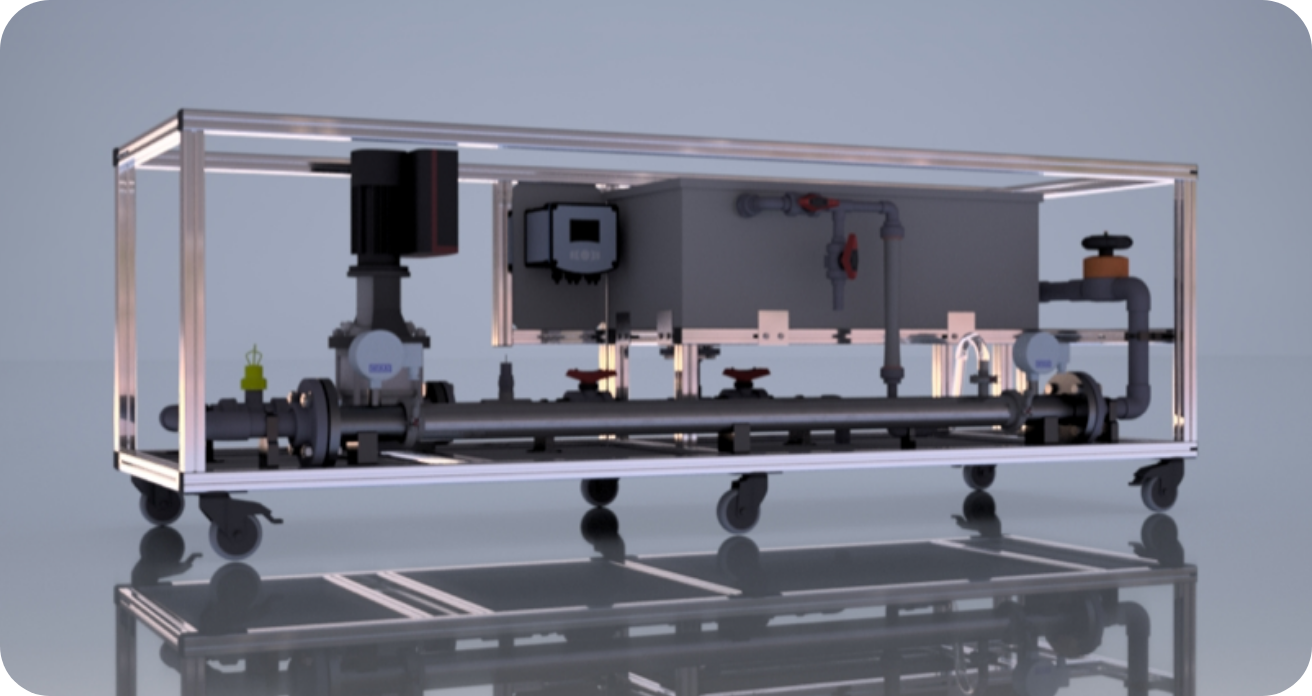

The membrane filtration system for micro- and ultra-filtration is designed to audit 4- and 8-inch spiral wraps, pipe sleeve membranes ranging from 1m2 to 30m2, as well as ceramic membranes when being used manually. All common types of membranes for micro- and ultra-filtration in various materials, such as PES, PVDF (organic), and aluminium oxide, Al2O3, can be placed in the membrane filtration system and inspected regarding their retention and filtration capacity.

The membrane filtration system works in batch mode. The filtrate is removed from the membrane filtration system while the concentrate is returned to the storage tank and concentrated as the process continues. Therefore, the unfiltered medium must be added to the storage tank.

| Membrane type (UF, MF) active membrane area | 1-30m2 |

| Weight | 120kg (without water filling), mobile aluminium frame |

| Measurements | |

| – Length | 2458mm |

| – Height | 843mm |

| – Depth | 797mm |

| Piping material | PVC |

| High-pressure pump with ELCB and dry-running protection | Grundfos CRNE 16000 L/h |

| max. working pressure | 3.8 bar |

| Filtrate capacity | depends on the medium |

| Electrical connected load 1 Electrical connected load 2 |

380 V / 50Hz / 16 A-2.2kW 220V / 50Hz / 550mA |

| Storage tank volume / material | 100 litres effective volume / polypropylene |

| Sealing material | EPDM |

| Measuring device type BÜRKERT

Multicell – with data logger |

overflow, operating pressure, temperature, filtrate capacity |